| Model No. | KS100 | KS150 | KS200 | KS250 |

|---|---|---|---|---|

| Power | 100W | 150W | 200W | 250W |

| Voltage | 120V / 230V (for choice) | |||

| Frequency | 50/60HZ | |||

| Temp. of blade | 5-8 seconds heating up to 600 ℃ | |||

| Cooling method | Air-cooled | |||

| Power Cord Length | 3 meter | |||

| Blade Length | 100mm | 150mm | 200mm | 250mm |

| Other Accessories | Allen key/Copper brush | |||

| Packing | Plastic tool box / Carton (for choice) | |||

| Item | Picture | Application |

|---|---|---|

| 30cm bendable blade (B05) |  |

Used in the groover for grooving of EPS foam, EPE foam, sponge etc. |

| Groover (G02) |  |

Use together with bendable blade for grooving of EPS foam, EPE foam, sponge etc. |

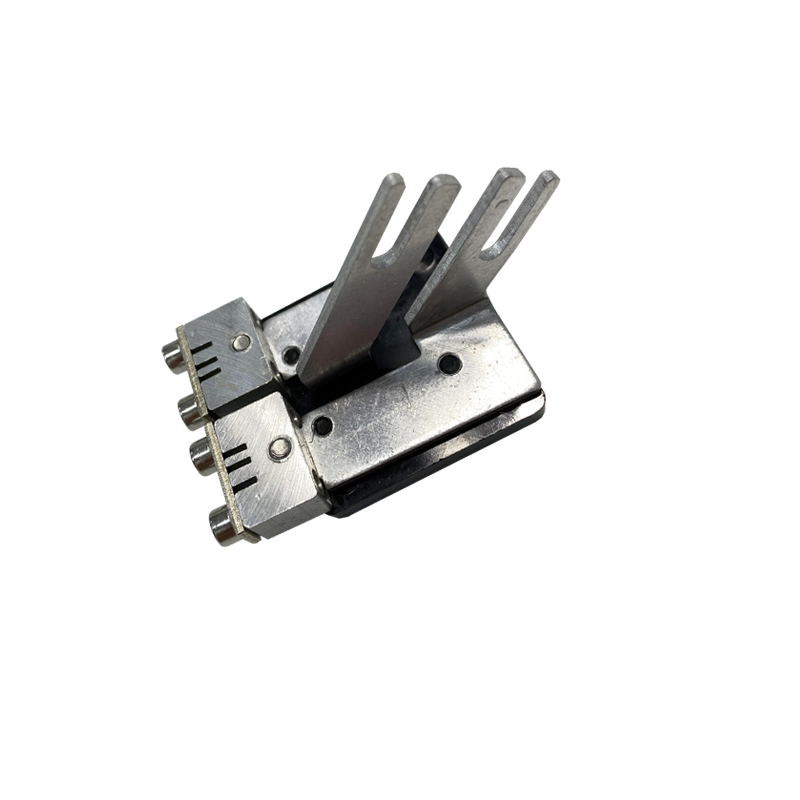

| Blade clamp for foam sculpturing (G01) |  |

Use together with the bendable blade, can be used for grooving of tube seat. |

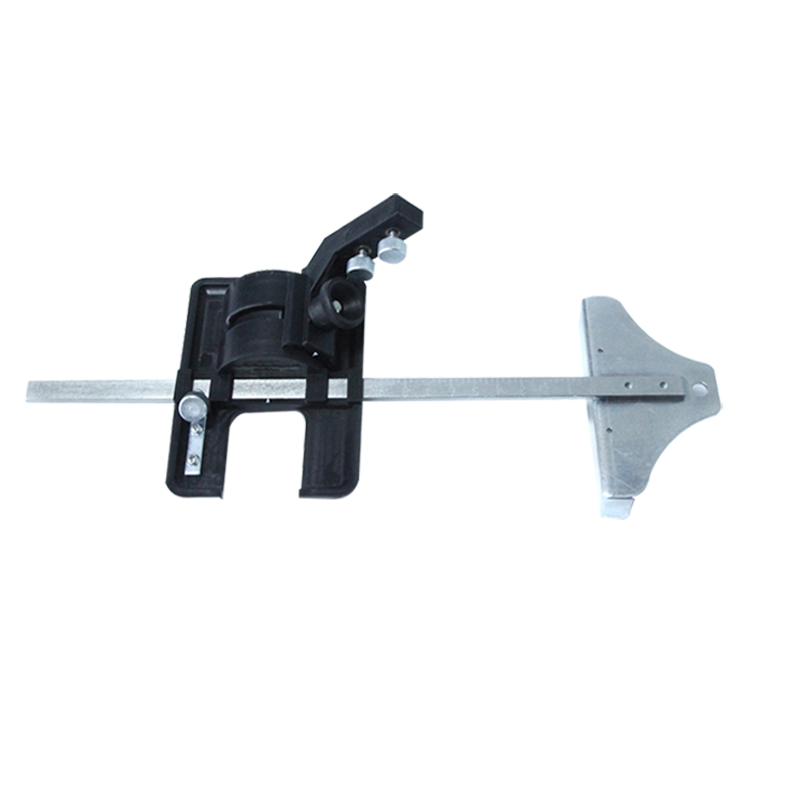

| Cutting guide (G04) |  |

Cutting guide for straight cutting and bevel cutting of EPS foam, EPE foam, sponge etc. |